Product Customization

With strong customization ability, Max can provide professional customized solutions and value-added services according to the individual needs of global customers, and help our customers to reduce cost and increase efficiency through customized products and services to improve the added value of the customer's products and the competitiveness of the enterprise.

Customization Channel

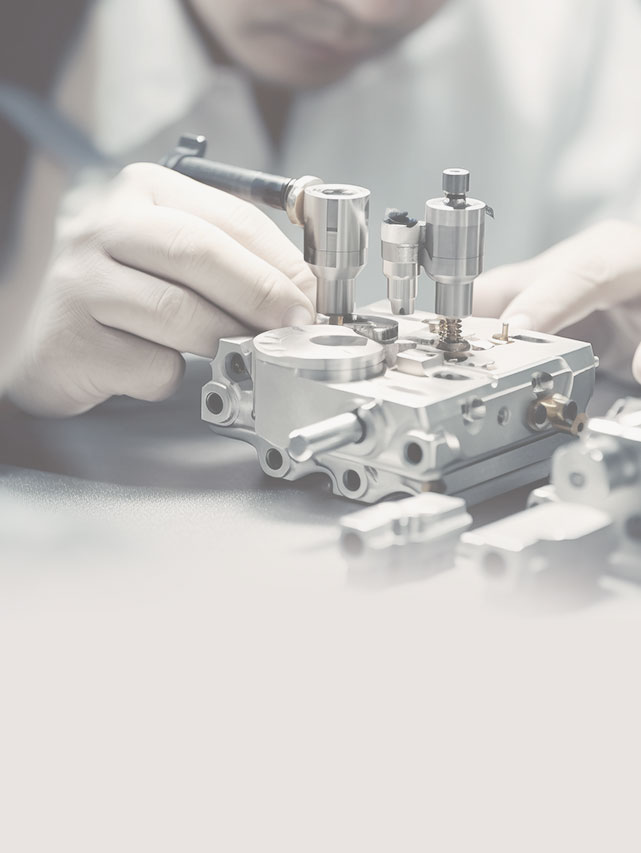

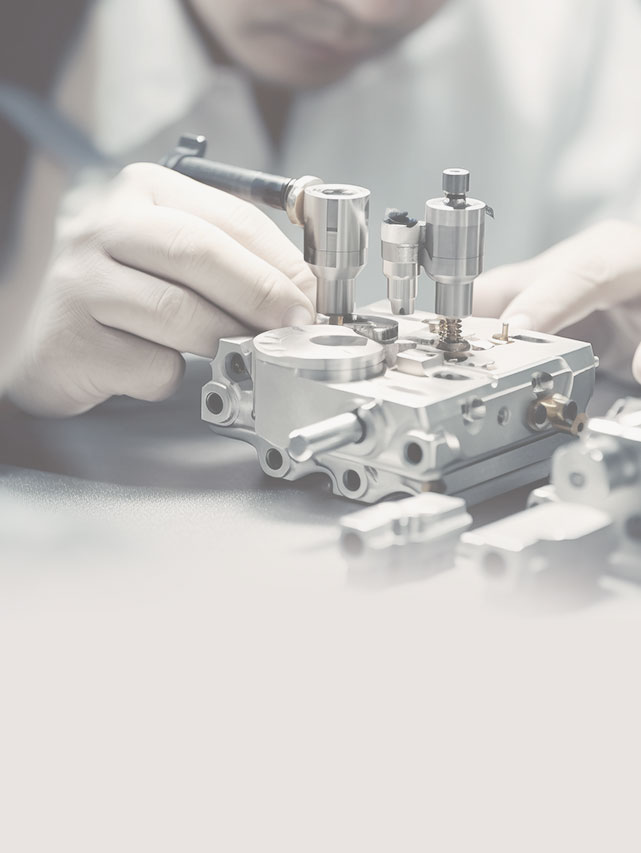

Mould Customization

Max has strong mold processing capacity, modular mold design, with professional and experienced mold design, assembly, commissioning and procurement project team; according to the customer's individual needs, quickly complete the mold, and provide samples. Maixu has more than one hundred sets of world-class mold processing equipments, such as Japan Shadick slow-feeding wire cutting, Japan Mitsubishi precision CNC electric pulse, high-precision CNC machining centers, precision measuring instruments, etc. Maixu owns the German mold software PLANTOOL, which can effectively shorten the cycle of molding, reduce the cost, and all-around ensure the product high-quality and meet the customer's delivery date quickly.

Customization Channel

Automation Customization

Has a strong self-chemical development capabilities, the current automation equipment technology software and hardware development engineers more than 50 people, with professional technology and rich experience, independent development of high-quality automation equipment. Currently automated assembly accounted for 80%, more than 300 sets of equipment, to achieve automatic inspection of the production line, fast delivery, and to ensure product consistency, in order to help customers succeed in providing automation solutions.

Customization Channel

Automation Customization

Has a strong self-chemical development capabilities, the current automation equipment technology software and hardware development engineers more than 50 people, with professional technology and rich experience, independent development of high-quality automation equipment. Currently automated assembly accounted for 80%, more than 300 sets of equipment, to achieve automatic inspection of the production line, fast delivery, and to ensure product consistency, in order to help customers succeed in providing automation solutions.

Customization Channel